Background - I have a plywood tank, glass front, that I built about two years ago. Up until about August '08, it housed an alligator snapping turtle. For reasons unknown, she unfortunately died (thread). So, I am left with an empty 4'x5'x18" tank, which I really can't move (see pics). This tank sits in the fish wall (thread) (original tank build thread)

Other background - I have a 75gal glass tank that until a year or so ago, was shaping up to be a nice brackish community. Then I introduced a green spotted puffer. It was fine for a few months, until it started eating or killing everything in the tank (thread). Now, I am left with a 75gal housing the GSP, with its "pet molly" (the only fish it has allowed to live).

Other other background - I also have a 10gal brackish holding tank (the short-term has turned into too long) housing a violet goby. It was originally in with the mudskipper, but it was having serious issues with nutrition - basically wasting away (thread). I moved it to the 10gal with the intention of fattening it up (which I did successfully) and returning it to the 75, where in a healthier state, I hoped it would be better able to fend for itself, perhaps with the aid of targeted feedings. However, while the goby was in the hospital tank, I acquired the GSP, and it started killing everything. It was clear that the goby and GSP would not be meeting.

So - the plan is thus: Since GSPs have the ability (or necessity, depending on the care sheet) to go full marine as adults, the plywood tank will be becoming a FOWLR tank. Once the GSP is moved, I will re-establish the 75 as a brackish community, get another mudskipper (yay!) and move teh goby back into a proper tank.

Ok, everyone caught up? This thread is to serve as the build of the plywood tank. The tank is currently sealed with MAS Epoxy resin with fiberglass tape on the seams. I tinted it a nice greenish brown color when I built it for the turtle. Before I turn it SW, I want to repaint it to a solid blue. The tank has a false back, which houses the filtration, which will probably just end up being a big refugium. I'll use a return pump along the order of 500-700GPH, and most of the flow will come from a large closed-loop system run by something along the lines of a Reeflo Snapper (2500gph).

Here are some preliminary pictures - I need to sand down the epoxy to get it clean and smooth. I had also sealed up some seams with silicone, which also needs to be removed, which I'm doing with a wire wheel in my rotozip.

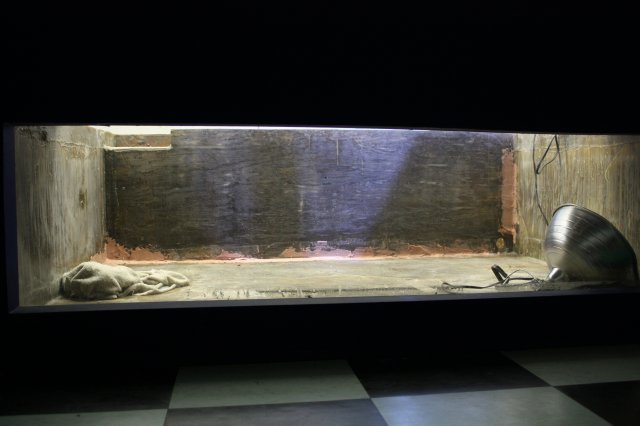

The tank empty and in position behind the fish wall

Closer

The false back with filtration

Showing the sanding

The epoxy paint, and some of the liverock I'm making for the tank

Some of the older liverock - the columns are going to be for a dock-type area in the brackish tank

Other background - I have a 75gal glass tank that until a year or so ago, was shaping up to be a nice brackish community. Then I introduced a green spotted puffer. It was fine for a few months, until it started eating or killing everything in the tank (thread). Now, I am left with a 75gal housing the GSP, with its "pet molly" (the only fish it has allowed to live).

Other other background - I also have a 10gal brackish holding tank (the short-term has turned into too long) housing a violet goby. It was originally in with the mudskipper, but it was having serious issues with nutrition - basically wasting away (thread). I moved it to the 10gal with the intention of fattening it up (which I did successfully) and returning it to the 75, where in a healthier state, I hoped it would be better able to fend for itself, perhaps with the aid of targeted feedings. However, while the goby was in the hospital tank, I acquired the GSP, and it started killing everything. It was clear that the goby and GSP would not be meeting.

So - the plan is thus: Since GSPs have the ability (or necessity, depending on the care sheet) to go full marine as adults, the plywood tank will be becoming a FOWLR tank. Once the GSP is moved, I will re-establish the 75 as a brackish community, get another mudskipper (yay!) and move teh goby back into a proper tank.

Ok, everyone caught up? This thread is to serve as the build of the plywood tank. The tank is currently sealed with MAS Epoxy resin with fiberglass tape on the seams. I tinted it a nice greenish brown color when I built it for the turtle. Before I turn it SW, I want to repaint it to a solid blue. The tank has a false back, which houses the filtration, which will probably just end up being a big refugium. I'll use a return pump along the order of 500-700GPH, and most of the flow will come from a large closed-loop system run by something along the lines of a Reeflo Snapper (2500gph).

Here are some preliminary pictures - I need to sand down the epoxy to get it clean and smooth. I had also sealed up some seams with silicone, which also needs to be removed, which I'm doing with a wire wheel in my rotozip.

The tank empty and in position behind the fish wall

Closer

The false back with filtration

Showing the sanding

The epoxy paint, and some of the liverock I'm making for the tank

Some of the older liverock - the columns are going to be for a dock-type area in the brackish tank