SYMPTOMS:

Rattling noise when starting up. Sometimes it fixes itself but most of the time you need to smack it a few times until it works.

PROBLEM:

Its pretty rare for the main body unit to malfunction since its just an electromagnet with no moving parts. Powerhead breaks are almost always from the shaft becoming misaligned. The rattling is caused by an unstable impeller shaft axis along with the impeller sliding up and down the shaft. The impeller wings end up hitting parts of the plastic.

SOLUTION:

Stabilizing the impeller shaft should solve the rattling problem. We are going to make a shaft end cap and a sleeve where the end cap is going to fit inside.

MATERIALS:

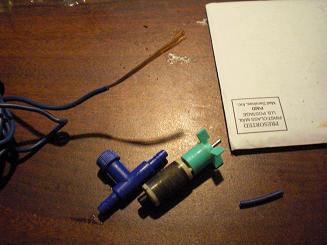

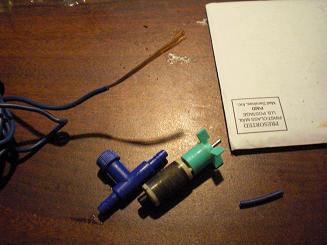

noisy powerhead (Aquaclear 20)

plastic airline connector

electrical wire (dunno guage... sorry)

airline tubing

household tools

PROCEDURE:

1) Take out impeller + shaft. There "should" be two little nubs holding the impeller in place but for some reason mine only had one..? :uhoh:

2) Cut off the tip of an airline connector. The size I needed for mine was in between the first and second ridge so I just sanded it down from the second.

3) Cut off ~2-3 cm of plastic wire coating.

4) Push ~3mm of wire coating onto the shaft and thread the airline connector end piece onto the loose end

5) Push the airline connector end piece onto the shaft by using the other side of the airline connector. You should have ~3mm of give for the impeller, but I think it depends on the model. You don't need to push the thing all the way in since you'll probably need to adjust it later anyway.

6) Cut off excess wire coating and sand until flush with airline connector (not shaft)

7) Cut off ~1cm of airline tubing and secure it onto the base where the shaft is supposed to hit on the other side. The length probably depends on your powerhead model. For mine there was a little nub in the middle where I just slipped the tubing onto.

8) Try to assemble and do a dry run. From here:

.....a) If everything doesn't fit, then you need to trim the silicon tubing or push the endcap further down

.....b) If the impeller still rattles, try pushing the endcap further down the shaft to eliminate the impeller from moving too much. Also make sure that the endcap is actually going into the airline tubing.

.....c) If the impeller is not moving, then try pushing the endcap upwards to allow more vertical movement.

9) step 8 requires some minute re-adjustments but afterwards you should get a silent powerhead.

OTHER THOUGHTS:

When you first assemble everything together, expect the fit to be slightly tighter since the plastic endcap has to slide into the airline tubing. Even though the fit is tighter, the impeller should not be affected.

Even brand new powerheads rattle SLIGHTLY when running dry. If the rattling isn't loud, then its probably fixed. Don't dry run for too long.

Rattling noise when starting up. Sometimes it fixes itself but most of the time you need to smack it a few times until it works.

PROBLEM:

Its pretty rare for the main body unit to malfunction since its just an electromagnet with no moving parts. Powerhead breaks are almost always from the shaft becoming misaligned. The rattling is caused by an unstable impeller shaft axis along with the impeller sliding up and down the shaft. The impeller wings end up hitting parts of the plastic.

SOLUTION:

Stabilizing the impeller shaft should solve the rattling problem. We are going to make a shaft end cap and a sleeve where the end cap is going to fit inside.

MATERIALS:

noisy powerhead (Aquaclear 20)

plastic airline connector

electrical wire (dunno guage... sorry)

airline tubing

household tools

PROCEDURE:

1) Take out impeller + shaft. There "should" be two little nubs holding the impeller in place but for some reason mine only had one..? :uhoh:

2) Cut off the tip of an airline connector. The size I needed for mine was in between the first and second ridge so I just sanded it down from the second.

3) Cut off ~2-3 cm of plastic wire coating.

4) Push ~3mm of wire coating onto the shaft and thread the airline connector end piece onto the loose end

5) Push the airline connector end piece onto the shaft by using the other side of the airline connector. You should have ~3mm of give for the impeller, but I think it depends on the model. You don't need to push the thing all the way in since you'll probably need to adjust it later anyway.

6) Cut off excess wire coating and sand until flush with airline connector (not shaft)

7) Cut off ~1cm of airline tubing and secure it onto the base where the shaft is supposed to hit on the other side. The length probably depends on your powerhead model. For mine there was a little nub in the middle where I just slipped the tubing onto.

8) Try to assemble and do a dry run. From here:

.....a) If everything doesn't fit, then you need to trim the silicon tubing or push the endcap further down

.....b) If the impeller still rattles, try pushing the endcap further down the shaft to eliminate the impeller from moving too much. Also make sure that the endcap is actually going into the airline tubing.

.....c) If the impeller is not moving, then try pushing the endcap upwards to allow more vertical movement.

9) step 8 requires some minute re-adjustments but afterwards you should get a silent powerhead.

OTHER THOUGHTS:

When you first assemble everything together, expect the fit to be slightly tighter since the plastic endcap has to slide into the airline tubing. Even though the fit is tighter, the impeller should not be affected.

Even brand new powerheads rattle SLIGHTLY when running dry. If the rattling isn't loud, then its probably fixed. Don't dry run for too long.