Ok, so before everyone tells me that they get 100 suction cups for $1.00 and so what's the problem, just replace them when they go bad, I have to say that in some circumstances it's a PITA!

In this tank, the cups for the plants keep coming loose, as well as the power head.

I made several retainers from rare earth magnets to hold the plants, as well as the power head to the tank.

A word of caution about the larger magnets....Be careful not to let the magnets fly into each other when holding one between your fingers. For instance, one is held in your hand and another on the countertop, and you inadvertently get too close to the magnet on the countertop, it's going to accelerate rapidly as it draws near the magnet you're holding and WHAM, you're going to feel it BIGTIME!

If you've ever smashed your finger with a hammer then you're in for the same experience here! This is no exaggeration!

The magnets I used are square for plants but the disk types are more aestically pleasing. I used what I had on hand (square) but the disks are probably better.

I used larger disk magnets for the Power Head.

I used the DX03 for the Power Head and the B882 for the plants.

http://www.kjmagnetics.com/

If I were using the disks for the plants I would probably go for the D82.....

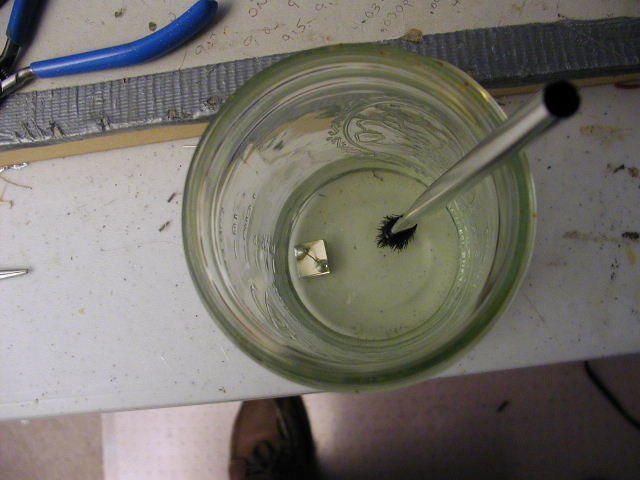

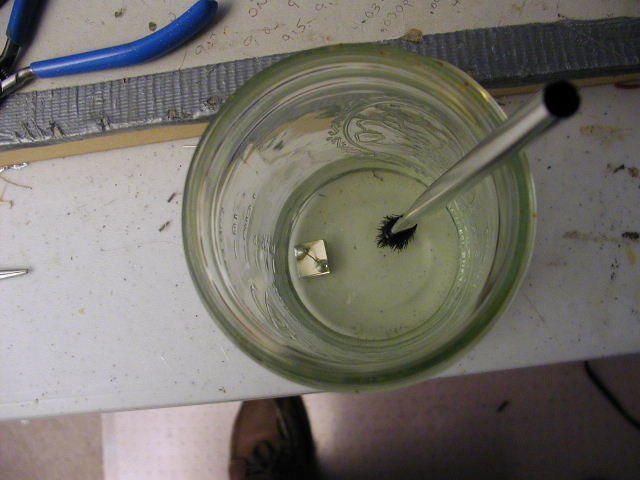

The process is pretty striaght forward. For the plants, you solder a retaining wire onto the magnet. I used electrical rosin core solder as there's really no strength required. Afterwards you need to clean the rosin flux from the magnets using Acetone or Alcohol.

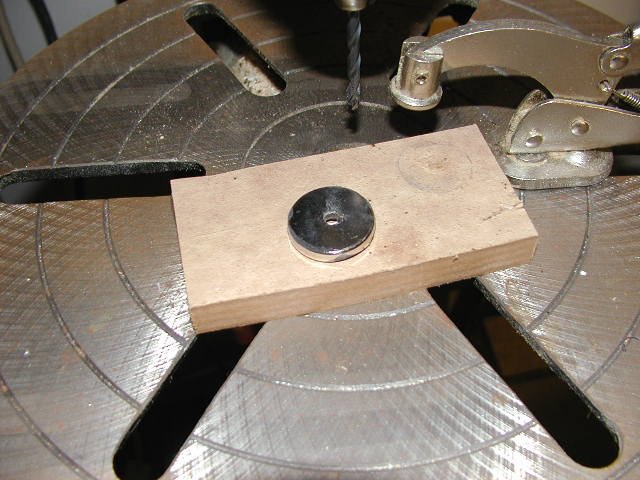

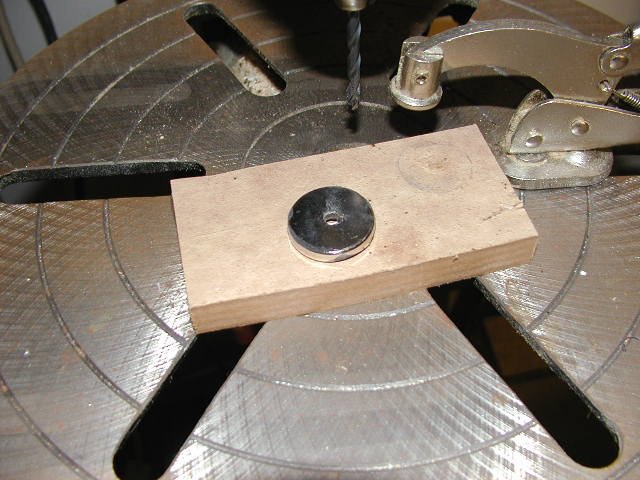

The power head attachment uses the disk magnet which I drilled to accomodate the barb used for the suction disk. I used J-B weld epoxy to attach it to the magnet.

The nice thing about the magnets used to hold the artificial plants is that you can "walk" them into position starting at the top of the tank from the outside by moving the magnets to position the plant.

*Just a side note on soldering to the magnets. I found it easier to start with a solder puddle on one corner of the magnet and then afterwards place the end of the wire into the re-heated puddle, then solder the remaining end afterwards.

In this tank, the cups for the plants keep coming loose, as well as the power head.

I made several retainers from rare earth magnets to hold the plants, as well as the power head to the tank.

A word of caution about the larger magnets....Be careful not to let the magnets fly into each other when holding one between your fingers. For instance, one is held in your hand and another on the countertop, and you inadvertently get too close to the magnet on the countertop, it's going to accelerate rapidly as it draws near the magnet you're holding and WHAM, you're going to feel it BIGTIME!

If you've ever smashed your finger with a hammer then you're in for the same experience here! This is no exaggeration!

The magnets I used are square for plants but the disk types are more aestically pleasing. I used what I had on hand (square) but the disks are probably better.

I used larger disk magnets for the Power Head.

I used the DX03 for the Power Head and the B882 for the plants.

http://www.kjmagnetics.com/

If I were using the disks for the plants I would probably go for the D82.....

The process is pretty striaght forward. For the plants, you solder a retaining wire onto the magnet. I used electrical rosin core solder as there's really no strength required. Afterwards you need to clean the rosin flux from the magnets using Acetone or Alcohol.

The power head attachment uses the disk magnet which I drilled to accomodate the barb used for the suction disk. I used J-B weld epoxy to attach it to the magnet.

The nice thing about the magnets used to hold the artificial plants is that you can "walk" them into position starting at the top of the tank from the outside by moving the magnets to position the plant.

*Just a side note on soldering to the magnets. I found it easier to start with a solder puddle on one corner of the magnet and then afterwards place the end of the wire into the re-heated puddle, then solder the remaining end afterwards.

Last edited: