Blame the plants, not me. If not for the plants, I would not have already upgraded my lighting once. If I had not built a new (temporary) light fixture, I would not have realized how little light my stock hood let in.

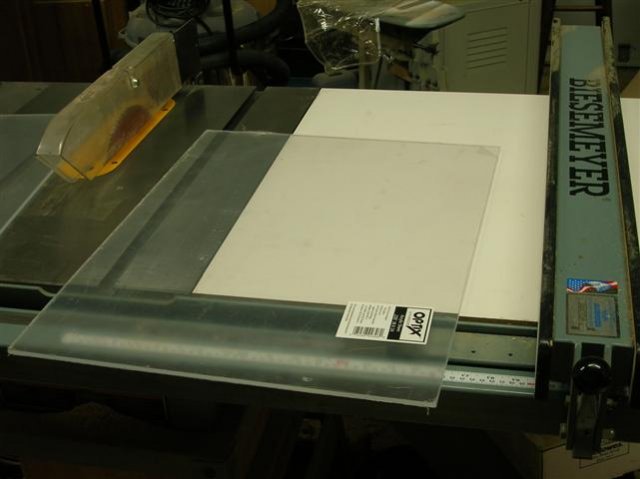

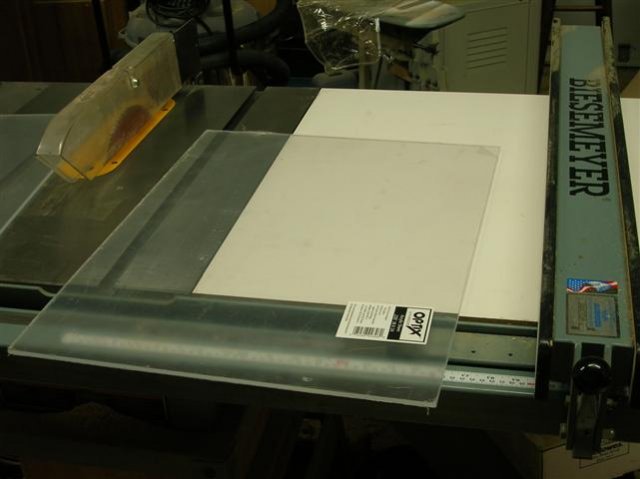

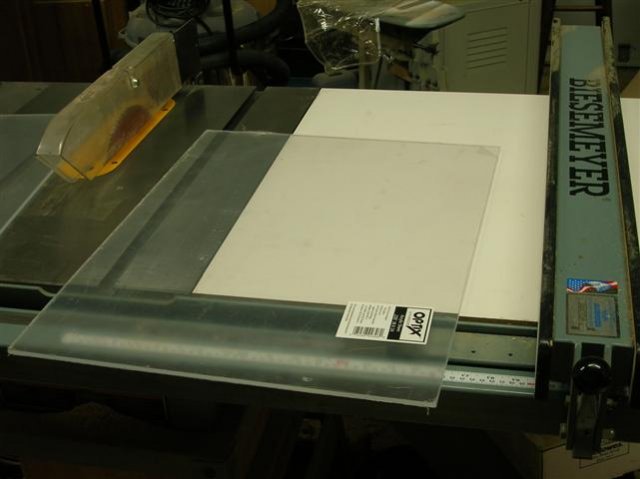

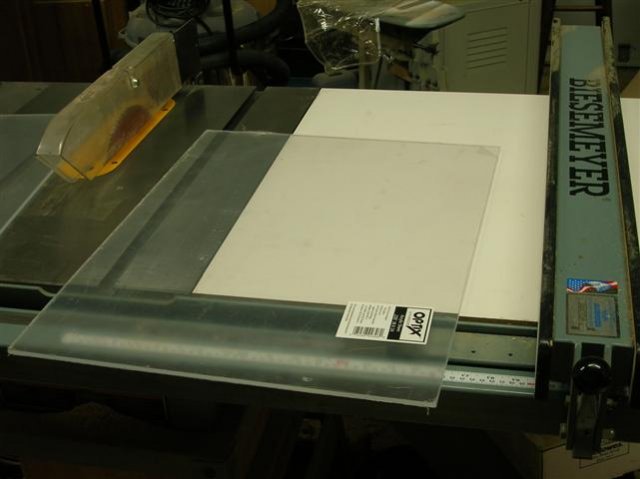

I plan on building a full canopy to match my current stand, but need to upgrade my lights now, not when I get around to the canopy. I had planned on making a glass hood, but glass is sharp and I am clumsy. While browsing around Lowes Friday, I found 1/4" 18x24" acrylic sheets for ~$12.

These sheets cut easily on the tablesaw but the little plastic fibers are hot. And sticky. After a few hours and some 5th degree plastic burns on my arms, I had a nice pile o' parts:

Super Glue seemed to work best for joining the pieces, and set very fast so I was able to move along pretty quick. The areas that are "boxed out" are to make room for the equipment entering and exiting the tank. The lighting setup that I am switching to has exposed bulbs that I want to keep as dry as possible.

The slits in the hood (the darker laminate is just there to show the slits) are for the trimable plastic inserts that are on the current hood, allowing me to reduce evaporation quite a bit.

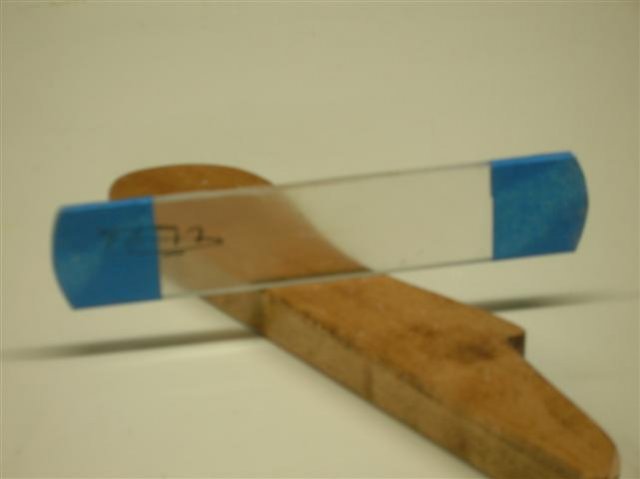

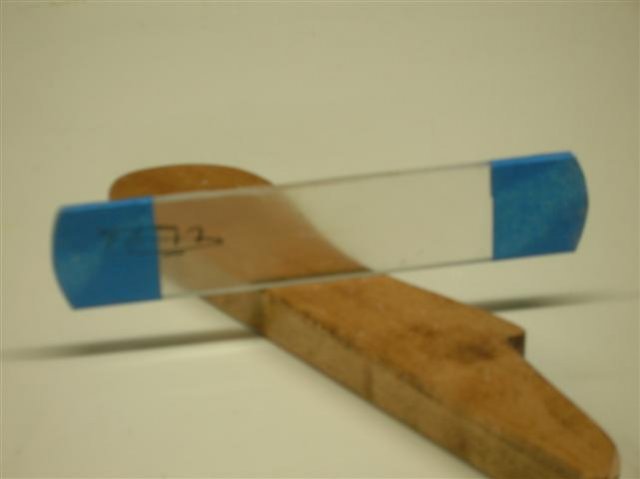

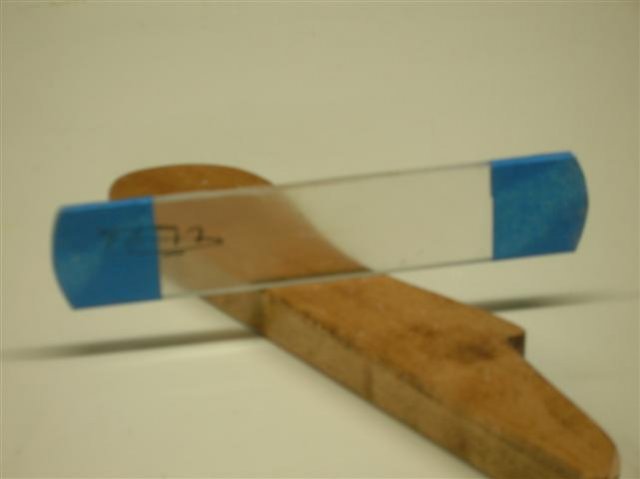

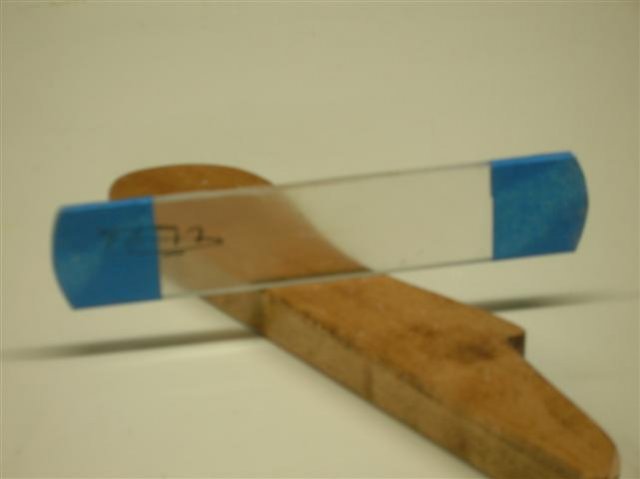

The removable front panels needed handles. I wanted to keep things clear, so I made my own out of scrap. Little pieces like handles are easier to work with while still attached to a larger piece. The curves were cut with a jigsaw with a fine toothed blade.

The handles were trimmed for length and the edges were sanded up to 2000 grit. I found out the hard way that this acrylic melts easily on a buffer, hence the sandpaper.

With the handles glued in place and the saw marks sand out of the edges, the rest of the protective plastic film could be removed. Ooooh, sparkly.

And finally, the new hood(s) in place.

Tomorrow, I will build a new (temporary again) light fixture. Long term, I plan on building a full canopy that incorporates this hood.

Thanks for looking,

Ben

I plan on building a full canopy to match my current stand, but need to upgrade my lights now, not when I get around to the canopy. I had planned on making a glass hood, but glass is sharp and I am clumsy. While browsing around Lowes Friday, I found 1/4" 18x24" acrylic sheets for ~$12.

These sheets cut easily on the tablesaw but the little plastic fibers are hot. And sticky. After a few hours and some 5th degree plastic burns on my arms, I had a nice pile o' parts:

Super Glue seemed to work best for joining the pieces, and set very fast so I was able to move along pretty quick. The areas that are "boxed out" are to make room for the equipment entering and exiting the tank. The lighting setup that I am switching to has exposed bulbs that I want to keep as dry as possible.

The slits in the hood (the darker laminate is just there to show the slits) are for the trimable plastic inserts that are on the current hood, allowing me to reduce evaporation quite a bit.

The removable front panels needed handles. I wanted to keep things clear, so I made my own out of scrap. Little pieces like handles are easier to work with while still attached to a larger piece. The curves were cut with a jigsaw with a fine toothed blade.

The handles were trimmed for length and the edges were sanded up to 2000 grit. I found out the hard way that this acrylic melts easily on a buffer, hence the sandpaper.

With the handles glued in place and the saw marks sand out of the edges, the rest of the protective plastic film could be removed. Ooooh, sparkly.

And finally, the new hood(s) in place.

Tomorrow, I will build a new (temporary again) light fixture. Long term, I plan on building a full canopy that incorporates this hood.

Thanks for looking,

Ben