I would like to change my filtration from HOB (AquaClear 110) on my 55-gal mbuna tank to a sump. I like my Aquaclear sponge media (cheap, reusable) and use the ceramic beads as my biofilter. My tank is overstocked, so I really need more filtration. (I would love to solve my overstock issue with more/bigger tanks, but . . . . . perhaps another time.) I could add a second AquaClear 110. However, as much as I like the HOB, I would like to increase the flexibilty of media options (such as floss for a fine filtration) and increase the water volume. I have seen some DIY projects that use the plastic drawers and Rubbermaid containers with a pump to create wet/dry set and wonder if this would be a way to increase the effective water volume of my set-up without increasing the tank size.

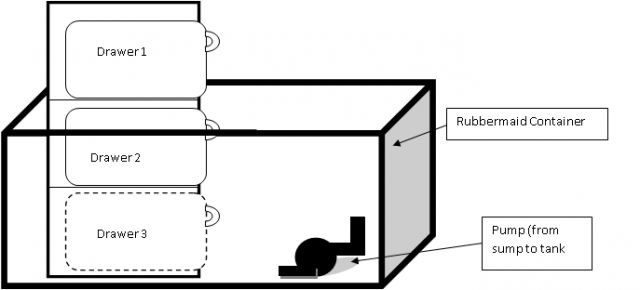

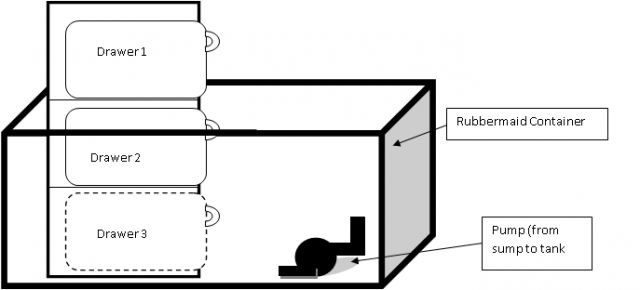

Just so everyone knows what style I am talking about, I have a basic sketch.

Questions:

1) Is there a rule of thumb for what the desired flowrate of the pump should be? Is this based on a desired number of water volume turnovers in the tank over time?

2) Can I keep most of the drawers under the water line and rely on the fact that as the pump returns water to the tank, it will cause the water in the drawers to fill the main reservoir, or will a system like this only work with the water trinkling through the drawers? (A little concerned with 'drippy noises')

3) How much bio filtration media is really needed? I have seen in other threads they talk about "gallons" of volume. However, I only use a few pints of ceramic beads and it seems to be fine. Is there a rule of thumb?

4) I am thinking about Drawer #1 using a sponge media (probably the AquaClear sponge or equivilent. Drawer #2 would be bio media (probably the ceramic beads). Drawer #3 could be used for charcoal or other chemical media if need. Sound like the correct arrangement?

5) Has anyone ever used a plastic screen laid over plastic grid ('light diffuser" material we use on the bottom of the tank to distribute the weight of rocks) to make a housing for polyester floss material? I have a vision of this resting over the top of my bio filter in Drawer #2. This would be after the 'course' sponge, so it would not clog as quickly.

6) I assume the tubing/piping sizes are a function of the discharge of the pump. I figure once I know the size of the pump, I can figure out the size of tubing/piping and the number of spray bars, etc.

I understand that this discussion does not include the overflow box. I can save that for a later thread, if needed. I searched for other discussions and have read a lot of information. Sorry if this is a repeated question.

Just so everyone knows what style I am talking about, I have a basic sketch.

Questions:

1) Is there a rule of thumb for what the desired flowrate of the pump should be? Is this based on a desired number of water volume turnovers in the tank over time?

2) Can I keep most of the drawers under the water line and rely on the fact that as the pump returns water to the tank, it will cause the water in the drawers to fill the main reservoir, or will a system like this only work with the water trinkling through the drawers? (A little concerned with 'drippy noises')

3) How much bio filtration media is really needed? I have seen in other threads they talk about "gallons" of volume. However, I only use a few pints of ceramic beads and it seems to be fine. Is there a rule of thumb?

4) I am thinking about Drawer #1 using a sponge media (probably the AquaClear sponge or equivilent. Drawer #2 would be bio media (probably the ceramic beads). Drawer #3 could be used for charcoal or other chemical media if need. Sound like the correct arrangement?

5) Has anyone ever used a plastic screen laid over plastic grid ('light diffuser" material we use on the bottom of the tank to distribute the weight of rocks) to make a housing for polyester floss material? I have a vision of this resting over the top of my bio filter in Drawer #2. This would be after the 'course' sponge, so it would not clog as quickly.

6) I assume the tubing/piping sizes are a function of the discharge of the pump. I figure once I know the size of the pump, I can figure out the size of tubing/piping and the number of spray bars, etc.

I understand that this discussion does not include the overflow box. I can save that for a later thread, if needed. I searched for other discussions and have read a lot of information. Sorry if this is a repeated question.