As for closing the lid and keeping it rigid...

I would use woodworking clamps (the very small ones)....Instead of clamping them directly on the bucket, I would make a wood or steel ring that seats around the bucket. Then have a solid round top (1cm wood)with openings for the hose and other stuff on the top.

Put clamps around, which are easy to remove, the wood top will spread the pressure much better than your current setup and at the same time, the clamps are easy to remove for maintenance/cleaning.

http://imghost.indiamart.com/data/K/H/MY-447979/CLAMP_250x250.jpg

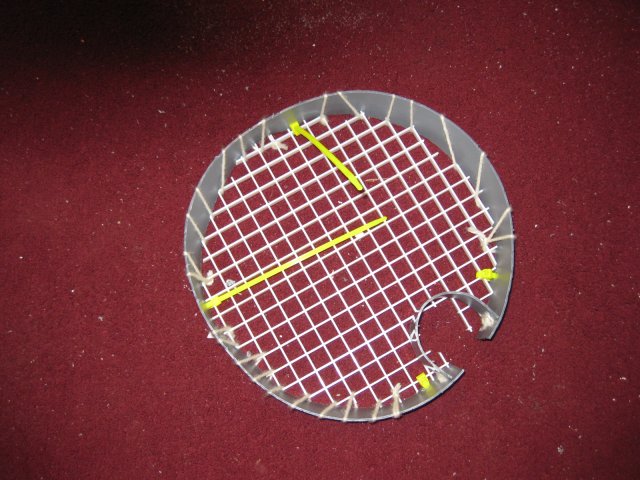

The clamp in the top of this picture is what I mean.

Just for the sake of it...I do not mean to replace the plastic top...just add the wood on top of that for equal spread of force closing it.

Checked back on the first page, and it seems not difficult to add...