99 Gallon Tank Journal

- Thread starter Luc

- Start date

I'm thinking of 2 pumps, Resun Penguins...

These are the specs:

MODEL:SP-6000

VOLT. :100~120V 220~240V

FREQ. :50/60Hz

POWER:40W

QMAX.:2800 L / Hr 740GPH

HMAX.:2.5m 8.2ft

PUMP OUTLET DIAMETER:¢13mm ¢1/2''

Given the corners, head and everything, I guess that I would end with about half of their output.

I can use them both internal and external, prefer external because I need to watch every bit of heat over here. Price for two of them would be equal to the single water-pump I'm looking at.

No details on that one yet. Simply a quiet external waterpump that is normally used to pump water around the house. Metal housing whereas the Resun's are plastic casings.

I like the redundancy idea and have seen good reviews on the Resun's but just afraid to end up with two pumps that are not strong enough.

Will be doing some more homework on that I guess. anybody with suggestions, please let me know.

Oh, for those who want to see pictures of the Resun: http://www.resun.com.cn/En/Products...lassID=107&PPro_ClassName=Velocity*Water*Pump

To limit flow, if necessary, I'll use a T with a valve on one end to adjust the amount that goes back into the sump. This way you don't limit or damage the pump and maximize your waterflow and filtration.

These are the specs:

MODEL:SP-6000

VOLT. :100~120V 220~240V

FREQ. :50/60Hz

POWER:40W

QMAX.:2800 L / Hr 740GPH

HMAX.:2.5m 8.2ft

PUMP OUTLET DIAMETER:¢13mm ¢1/2''

Given the corners, head and everything, I guess that I would end with about half of their output.

I can use them both internal and external, prefer external because I need to watch every bit of heat over here. Price for two of them would be equal to the single water-pump I'm looking at.

No details on that one yet. Simply a quiet external waterpump that is normally used to pump water around the house. Metal housing whereas the Resun's are plastic casings.

I like the redundancy idea and have seen good reviews on the Resun's but just afraid to end up with two pumps that are not strong enough.

Will be doing some more homework on that I guess. anybody with suggestions, please let me know.

Oh, for those who want to see pictures of the Resun: http://www.resun.com.cn/En/Products...lassID=107&PPro_ClassName=Velocity*Water*Pump

To limit flow, if necessary, I'll use a T with a valve on one end to adjust the amount that goes back into the sump. This way you don't limit or damage the pump and maximize your waterflow and filtration.

1 more question:

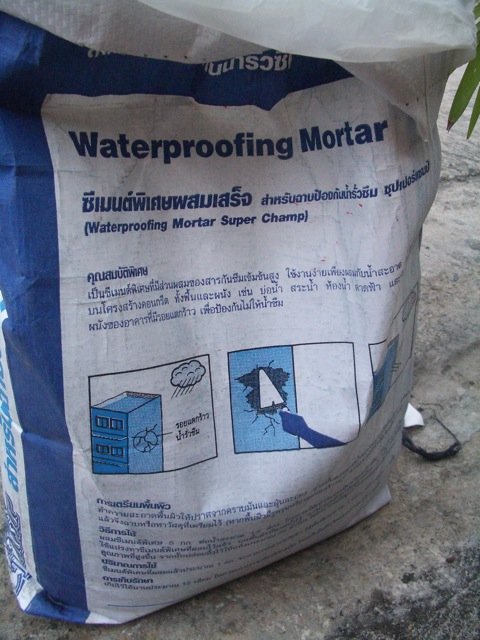

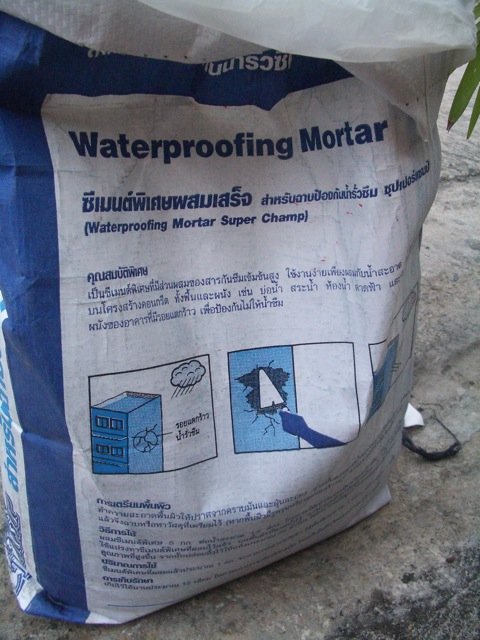

for the background, I'm using cement, just add water, stir it and ready to go.

To color it, I'm planning to use Iron-oxide which comes in variety of color.

My plan is to mix some yellow, red and black with water before adding the cement.

The resulting brownish color should save me a headache painting grey cement.

Questions:

- Iron Oxide, anybody has experience with that? Toxic for Fish? Or plants?

- Once the cement is dry, it's label says waterproof. I asked in the shop, and they assured me it would be ok under water.

But with the idea of the iron-oxide to color it, again...comments/suggestions very welcome.

Otherwise I'll have to get some epoxy-coating to seal the cement from contact with water.

for the background, I'm using cement, just add water, stir it and ready to go.

To color it, I'm planning to use Iron-oxide which comes in variety of color.

My plan is to mix some yellow, red and black with water before adding the cement.

The resulting brownish color should save me a headache painting grey cement.

Questions:

- Iron Oxide, anybody has experience with that? Toxic for Fish? Or plants?

- Once the cement is dry, it's label says waterproof. I asked in the shop, and they assured me it would be ok under water.

But with the idea of the iron-oxide to color it, again...comments/suggestions very welcome.

Otherwise I'll have to get some epoxy-coating to seal the cement from contact with water.

Background is getting there. I decided to go with the iron-oxide to color the cement and avoid painting or coloring the epoxy later.

I'm happy with the result. The color is still quite red, but after drying, it works out to a pale red/brown color. I hope that a layer of epoxy with some sand will just bring it where I plan to be.

Anyhow, some pictures. Cement was easy, just try a bit with mixing the colors first in water, once you have the right color, add cement and mix it until it's a nice stiff mass.

I just used two putty-knives to put it on. Works great. A spray-bottle of water to keep it damp.

I'm happy with the result. The color is still quite red, but after drying, it works out to a pale red/brown color. I hope that a layer of epoxy with some sand will just bring it where I plan to be.

Anyhow, some pictures. Cement was easy, just try a bit with mixing the colors first in water, once you have the right color, add cement and mix it until it's a nice stiff mass.

I just used two putty-knives to put it on. Works great. A spray-bottle of water to keep it damp.

Well, yesterday and today where mainly taken by moving the 79G to make space for the 99G. Gonna be 4 meters of stand with 2.70m of fishtank...(I really don't have MTS...really..)

Sad, the 79 was getting nicely in shape, but also an opportunity to take everything out and wash the substrate, which I hate but need to do every three to four months or so. (I got a good layer of minimum 10cm at the front, going to 15 in the back left, around 10 in the back right. ( down the slope towards the filter intakes. )

Anyhow, this is what it looks like now. Tomorrow the rest of the plants will move back in until the 99G is ready. Once we get there, I'll start splitting some of the plants.

Sad, the 79 was getting nicely in shape, but also an opportunity to take everything out and wash the substrate, which I hate but need to do every three to four months or so. (I got a good layer of minimum 10cm at the front, going to 15 in the back left, around 10 in the back right. ( down the slope towards the filter intakes. )

Anyhow, this is what it looks like now. Tomorrow the rest of the plants will move back in until the 99G is ready. Once we get there, I'll start splitting some of the plants.

The background has been drying nicely.

Yesterday it looked quite dark brown and glossy, but now it starts to get more pale red/brown.

Still hoping to get some help on the questions for the concrete...

1. Cement + Iron Oxide, cover it with Expoxy-coating yes/no?

Realize it's year-end, so guess I'll end up coating it to be safe and done.

Happy and Healthy 2009 everybody, hope you'll enjoy it.

Yesterday it looked quite dark brown and glossy, but now it starts to get more pale red/brown.

Still hoping to get some help on the questions for the concrete...

1. Cement + Iron Oxide, cover it with Expoxy-coating yes/no?

Realize it's year-end, so guess I'll end up coating it to be safe and done.

Happy and Healthy 2009 everybody, hope you'll enjoy it.

Been a couple of days, but plans are shaping up.

I've finished the top of the stand. Can start moving the tank but have to wait a couple of days for new styrofoam (bottom support). Had 1 bad experience with that, since then, no matter if the stand is the same or the support is horizontal, whatever.....just to repeat it once more:

Always change the piece of styrofoam under your tank with a new one when you move your tank!!!

Tested strenght and had to make sure the glue would bond well. Passed both tests.

Also started working on the mains water-filter. Still need to change the carbon and resin in the coming weeks.

Not using the ceramic filter-unit yet. Might plump that one into an automated top-off system in the future.

Ok, back to the subject. On my sump. I'll get a 23G (60x30x40cm LxWxH) tank this weekend. Together with the 10G (50x25x40cm) I have already, this will become my sump.

The fit next to each other in the right-most compartment of the stand.

The overflow box will be on the 79G stand, feeding the 23G.

I'll go with the advise of having 2 pumps.

Figured also that the 23G tank would be all the filtration, while the 10G will be the equipment-box.

What goes in there:

1. Heater

2. Return-Pumps (2)

3. CO2 Reactor (home-made, will post some pictures later)

4. Chiller (home-made, please look at my first post "DIY Chiller")

The Chiller is an old dorm-fridge, but modified. It's enough for me to keep the edge of the hot days here.

Currently it's still using the fridge-case as the actual cooling-zone, but I can take away the case, seal the copper tubes and then put them straight into the 10 gallon. Isolate around the outside and put it on a proper temp-controller.

Saves a ton of space since the compressor is on a rack by itself already.

Now, for the 23G sump-part, I want to run a 100% wet sump.

I think of 4 compartments:

1. Inlet with Bioballs

2. Ceramic Rings

3. Ceramic Rings (smaller size)

4. Compartment connecting to the equipment-10G (can use for Carbon or more Ceramic)

Will make some drawings first, but scanner at work so later this week.

Any suggestions / comments on above setup, very welcome...

By the way, decided to try and do without epoxy coating on the cement.

Curing it over a couple of weeks time. See how that works and how everything holds up.

Again, anybody send in comments on that, not done yet so could change my mind.

I've finished the top of the stand. Can start moving the tank but have to wait a couple of days for new styrofoam (bottom support). Had 1 bad experience with that, since then, no matter if the stand is the same or the support is horizontal, whatever.....just to repeat it once more:

Always change the piece of styrofoam under your tank with a new one when you move your tank!!!

Tested strenght and had to make sure the glue would bond well. Passed both tests.

Also started working on the mains water-filter. Still need to change the carbon and resin in the coming weeks.

Not using the ceramic filter-unit yet. Might plump that one into an automated top-off system in the future.

Ok, back to the subject. On my sump. I'll get a 23G (60x30x40cm LxWxH) tank this weekend. Together with the 10G (50x25x40cm) I have already, this will become my sump.

The fit next to each other in the right-most compartment of the stand.

The overflow box will be on the 79G stand, feeding the 23G.

I'll go with the advise of having 2 pumps.

Figured also that the 23G tank would be all the filtration, while the 10G will be the equipment-box.

What goes in there:

1. Heater

2. Return-Pumps (2)

3. CO2 Reactor (home-made, will post some pictures later)

4. Chiller (home-made, please look at my first post "DIY Chiller")

The Chiller is an old dorm-fridge, but modified. It's enough for me to keep the edge of the hot days here.

Currently it's still using the fridge-case as the actual cooling-zone, but I can take away the case, seal the copper tubes and then put them straight into the 10 gallon. Isolate around the outside and put it on a proper temp-controller.

Saves a ton of space since the compressor is on a rack by itself already.

Now, for the 23G sump-part, I want to run a 100% wet sump.

I think of 4 compartments:

1. Inlet with Bioballs

2. Ceramic Rings

3. Ceramic Rings (smaller size)

4. Compartment connecting to the equipment-10G (can use for Carbon or more Ceramic)

Will make some drawings first, but scanner at work so later this week.

Any suggestions / comments on above setup, very welcome...

By the way, decided to try and do without epoxy coating on the cement.

Curing it over a couple of weeks time. See how that works and how everything holds up.

Again, anybody send in comments on that, not done yet so could change my mind.