Finally, I'm now waiting for the last bits to dry.

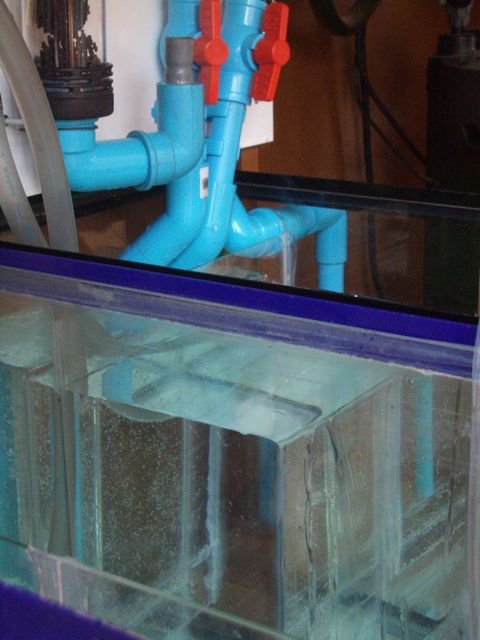

Once done, I can switch on the pumps. A lot finished today and I'm quite happy with it. The overflow box and the 1" hoses used for that are working. To get them running, I've used small garden-hose sprinklers. You know, those small plastic screw-fittings that go into a hose, connect it to a tap and you're ready. Not sure how you call them again, but you'll find them in any home-DIY shop.

I took one, take off the plastic top, and you have a nice opening where you put a airline on. Take a plastic check-valve and you have a perfect syphon-starter.

Next, I finished the CO2 reactor and hooked it up. Follows the same principle as all those DIY and commercially available reactors. I used whatever I had lying around and with silicone and glue, the end-result looks acceptable.

Two L-shaped screws in the board and a metal wire around the bottom-outlet and it's stable, secured and ready.

I've tried some with the overflow-pipes and bits and pieces of pvc-pipes to reduce the noise. Looks ok now, but will work on some improvements.

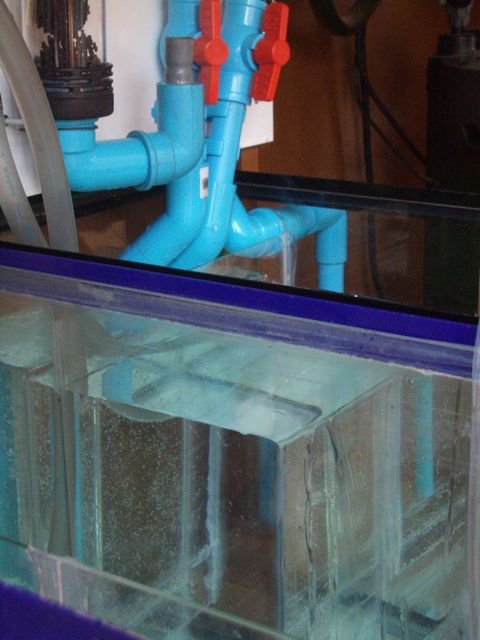

Then, I've at least done half of a wet-test. Water in the overflow, through syphon and down to the sump. Then through the sump into the equipment tank. Some small leaks at first between 2 compartments, but solved in no-time with silicone.

Another problem was a seal leaking on the front connection between the two tanks. Since changing water is going to be done by tap water in the equipment-sump and draining from the filter-sump, I thought better to put a valve between the two so that there's no 'bleeding' in the process and it'll speed up the water-changing. So, seal-leak solved, valve in-between, reconnected and water-proof this time.

Now, I also had 1 pump running for a couple of minutes and I found:

1. The pump seems to have no problem with any head-loss. Water is really pumping like crazy though it is into an empty tank so that will reduce a bit once testing on a full tank starts.

2. A small leak on the return-drain of the pump. Repaired .and waiting for it to dry.

3. I have a generous over-capacity from what I saw on that couple of minutes running. Good, better safe than sorry. Water will be pumping around and get filtered like crazy.

What more? Oh, yes, I've installed a small T8 light over the sump-compartment. Looks sweeet...Love it, never mind the display-tank...lol

Ok, let's have the pictures first.