Here is my "How-To"(according to how I did it). I finish by adding what I would have done differently.

Supplies:

3/4" Plywood sheet(I purchased a full sheet of Birch)

60" of 1/2" square rod(used to brace or allow the top to sit on your tank)

24" of 3/4" x 4" board(solid, could be scrap from around your house)

10 2" L-brackets(used to attach wood)

12 1" L-brackets(used to attach light "fixtures"...I'll explain)

100 pack of 3/4" flat head wood screws(used to attach all L-brackets)

~20 1" #6 flat head wood screws(used to attach 1/2" square rod to hood)

12" of 1/16" cable(used to hold the liftable portion when open)

2 3/4" # 6round head wood screws(used to hold down cable)

2 1" #6 washers(used with screws to hold down cable)

6 rubber insulated outdoor light sockets

20' #14 AWG wire Black

20' #14 AWG wire White

1 15 amp double switch

1 stainable double switch switch cover

6 compact fluorescent bulbs(I used two 26, two 20, and two 15 watts)

Staples(used with staple gun to attach wire)

14 #14 AWG wire caps

Electrical tape

6' of vinyl tubing(3/8" internal diameter)

1 heavy duty(15-20 amp) plug

Stain of choice

Polyurethane of choice

Primer(not really needed, but I used it anyway for the paint)

Semi Gloss White Paint

Brushes(I used 3, but you if you don't want to wash, get more)

2 hinges of choice

1 knob of choice

Tools needed(according to what I used):

Circular Saw: Finishing blade

Jig Saw: Any wood blade

Drill:1/8" bit, 1.25" bit, Phillips head

Obvious tools(measuring tape, square, screw driver, utility knife,etc...)

Stable Gun

Once you have everything, here's a glossed over "how to"

Cut wood to the appropriate dimensions(see first post for design). I cut at a 45" angle so that everything would look nice. However, if you decide to use solid wood(see recommendations) this isn't required. Cut your square rod into lengths so that you can put a piece on each edge of the hood(see pictures). According to the design, my back piece of wood was one solid piece with a cut out for the filter. I changed this, it is two separate pieces. In one of them cut out a hole for the switch (make sure it fits). Once everything is cut, sand the edges, and make sure everything fits together the way it should(flat edges, angles coming together, your lengths are correct, etc...).

You will also use the 3/4" solid board. This will be cut into 6 3" inch squares

to be used as your light socket "fixtures". Using the 1.25" bit, drill a whole in the center. Paint(primer first) these white. Paint the square rods white as well. Coat well with white paint.

Once it's all sanded and fits nicely, I stained all of it. (It has been suggested to wait to stain until it's all together: see above posts). I then taped off the edges and exterior portions. Primer the inside portion. Paint the inside portion with the white paint(I don't believe the primer is really necessary, but whatever. I painted several coats to make it as white as possible). It's white to reflect. Throughout this forum, white paint has been the reflective material of choice for costs and ease. Aluminum foil should not be considered.

Everything is painted, and the exterior has one coat of stain. Now, build your hood. See design and pictures. Use 2" L-brackets with 3/4" #6 flat head wood screws to attach. According to my design, I used 10 L-brackets and it's held together nicely. Attach your square rods after the hood is built. These should be measured carefully to make sure they are level all the way around. This ensures your hood will be level when it is on your tank. Also attach your "light fixture" wood squares. Use 1" L-brackets. These should be place however you want, but you can see how I did it in my sketch.

So, now it is built. I recommend testing to make sure it fits. Certain things may have to be adjusted according your specific tank needs.

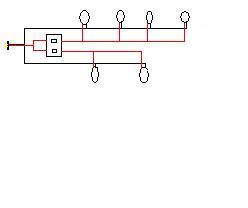

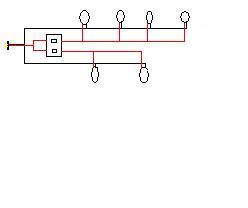

Now, the fun part: wiring. Slide your outdoor, rubber insulated, light sockets into the "fixtures". I didn't glue these because with the paint and 1.25" hole, they fit snugly. You can glue these if you want. I've attached a crude drawing of the wiring. Things important to remember: Wire in parallel and switch must be on the "live", white(in the drawing red) wire. I used 14 AWG wire to really ensure high quality power. You can use 16 AWG. Do not use 18 AWG for this project. Wire using wire caps. I used electrical tape for redundancy over the wire caps given the exposure to evaporated water. I made my "plug wire" 6 ft long. Additionally, I "wrapped" the "plug wire" in vinyl tubing and then wrapped that with electrical tape to protect my wire.(I cut the tubing down the center, placed the electrical wires inside, and then wrapped in electrical tape to seal it all up). Wiring to the plug is easy. Using the drawing this should be pretty easy. Feel confident, wiring is not as scary as it seems. After everything is wired up, and you are sure your circuit works, mount the switch if you haven't already(I left it unmounted so it was easier to work with).

I then filled every crack I could(the cracks belonging to the lifting cover are exempt) with wood putty.

At this point I touched up the inside white paint. I then sanded the outside down slightly(at the minimum to make your dried wood putty look good), and restained(including the stainable switch cover). I applied two coats of polyurethane. Install the knob and hinges. Then, mount the bracing cable(as seen in the pictures). I can't tell you how long to make this. I did it to fit my situation. I didn't want the top to hit the wall, so I opened it up until was almost touching the wall and installed the cable. Again, see the pictures. This is it. It's done.

Took me a little over 3 weekends including all the problems I encountered as noted in the above posts.

In a kind of random fashion, here are a few things I would have done differently.

First off, given my particular dimensions, I would have used 3/4 inch solid wood instead of ply. I mean, it's got a nice veneer(Birch), but I could have worked with it a little more if it were solid wood. And, give my dimensions, I could have used 3/4" x 12" boards and cut them down to size. The downside of this is that when I build the matching base, I couldn't find a 38" sheet.

I used a circular saw to cut my wood, which made some of the cuts a little off from straight. If I could do it again, I would have used a table saw(my landlord actually told me after I had made my cuts that I could have borrowed his table saw). The cuts would have been closer to straight. I addressed the uneven cuts by filling the cracks with wood putty, so it looks good. The cracks in the liftable portion couldn't be filled with wood putty, so I do wish these cuts were perfectly straight.

I filled the cracks after assembly. I would recommend putting putty in the cracks during assembly(before screwing in the L-brackets). You would still have to come back and add more, but it would have been easier I suspect.

Remember, always: "Measure Twice, Cut Once" & "There's Always Time To Do It Right"