I feel good...

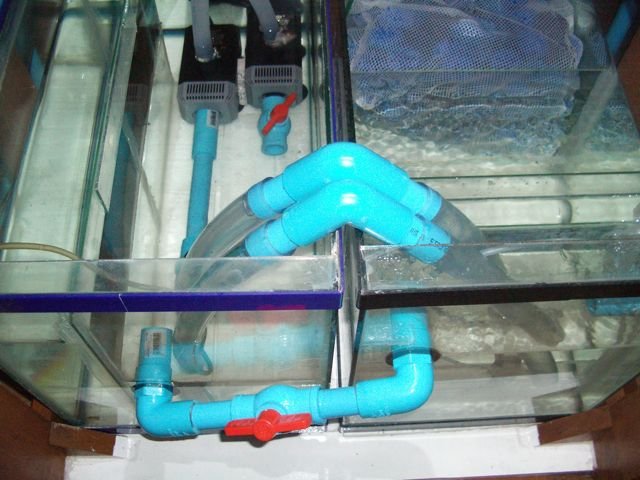

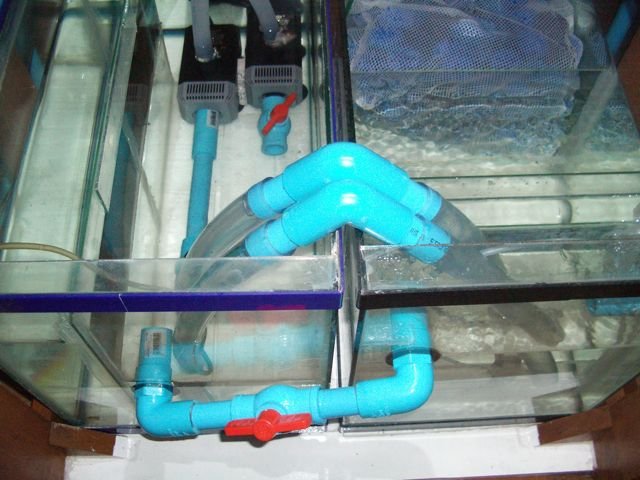

As mentioned yesterday, bummer, not enough throughput in between the two sump-tanks. So today I did some testing, 2 elbows, 1" diameter. Both with tubes attached, making syphon-tubes that would nicely stay center on the rim of both tanks. Works like a charm for now. Enough throughput there and no drilling or anything (yet).

So then of course, the next bottleneck shows up, which is the two drains from the overflow-box. This one was expected though, there's no stockman's pipe on it yet and the two pipes are very high up in the box. So toilets sounds all over the place. It slows down the flow because of all the air that gets down the tubes. Topping it off, the level in the main tank gets very high to get enough pressure into the overflow box. That means a higher level of accidents and restricted waterflow. Currently, the pumps still have 25% more capacity than I get from those 1" drain-lines. Far too much, I want that to get to at least zero or a minus. (I've restricted both pump-inlets with a loose valve over the inlet. Closed the valve 1/3 and because it is loose, the pump gets hardly and resistance but less water even so. You can see them in the pictures.)

That'll be a job for the weekend though. Good news is that with a few minutes work I will have solved the backflow problem as well. If you look at the pictures you'll see 4 vertical valves. These return to the display-tank. Left to right:

Number 1 is left back corner: backflow solved and ok, giving only and inch of water back into the sump.

Number 2 is the spraybar on the left side, also ok, an inch of water into the sump.

Number 3 is the right front corner.This one still needs a hole drilled, will be done this weekend.

Number 4 is the left front corner with the CO2-reactor built in. This one is ok as well.

Filled and running, the sump with the return-pumps is about half full. So backflow and stop on the overflow-box has sufficient space and nicely settles in the sump.

So this weekend, I hope to get a fix on the standpipes and clear the back-flow issue. Then do more testing with all filter-media inside, though with bioballs in there, there's no slowdown that I could see. Great stuff, it's just a great sight to see that stuff running and balanced.

The CO2-reactor runs as prayed for. Initially quite some air-build up in the lines, but after a couple of minutes it settled and emptied itself. Can't wait to see how that will run with CO2 and plant-grow.

I've had guppies and an angel testing the water for 2 weeks, no problems at all. Took them out last weekend, back to their friends. A pleco is now cleaning the tank for me. (Looks like a safari pattern right now..lol).

All in all, just can't wait for the tank to start running and at the same time, start getting the electric done. Great....

Ok, some pictures...

As mentioned yesterday, bummer, not enough throughput in between the two sump-tanks. So today I did some testing, 2 elbows, 1" diameter. Both with tubes attached, making syphon-tubes that would nicely stay center on the rim of both tanks. Works like a charm for now. Enough throughput there and no drilling or anything (yet).

So then of course, the next bottleneck shows up, which is the two drains from the overflow-box. This one was expected though, there's no stockman's pipe on it yet and the two pipes are very high up in the box. So toilets sounds all over the place. It slows down the flow because of all the air that gets down the tubes. Topping it off, the level in the main tank gets very high to get enough pressure into the overflow box. That means a higher level of accidents and restricted waterflow. Currently, the pumps still have 25% more capacity than I get from those 1" drain-lines. Far too much, I want that to get to at least zero or a minus. (I've restricted both pump-inlets with a loose valve over the inlet. Closed the valve 1/3 and because it is loose, the pump gets hardly and resistance but less water even so. You can see them in the pictures.)

That'll be a job for the weekend though. Good news is that with a few minutes work I will have solved the backflow problem as well. If you look at the pictures you'll see 4 vertical valves. These return to the display-tank. Left to right:

Number 1 is left back corner: backflow solved and ok, giving only and inch of water back into the sump.

Number 2 is the spraybar on the left side, also ok, an inch of water into the sump.

Number 3 is the right front corner.This one still needs a hole drilled, will be done this weekend.

Number 4 is the left front corner with the CO2-reactor built in. This one is ok as well.

Filled and running, the sump with the return-pumps is about half full. So backflow and stop on the overflow-box has sufficient space and nicely settles in the sump.

So this weekend, I hope to get a fix on the standpipes and clear the back-flow issue. Then do more testing with all filter-media inside, though with bioballs in there, there's no slowdown that I could see. Great stuff, it's just a great sight to see that stuff running and balanced.

The CO2-reactor runs as prayed for. Initially quite some air-build up in the lines, but after a couple of minutes it settled and emptied itself. Can't wait to see how that will run with CO2 and plant-grow.

I've had guppies and an angel testing the water for 2 weeks, no problems at all. Took them out last weekend, back to their friends. A pleco is now cleaning the tank for me. (Looks like a safari pattern right now..lol).

All in all, just can't wait for the tank to start running and at the same time, start getting the electric done. Great....

Ok, some pictures...