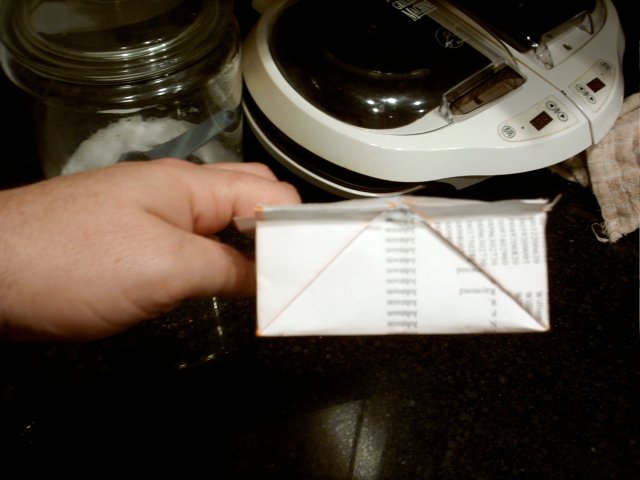

Ok, here's step by step. Ignore the cuts in the corner. Paper doesn't give any like the liner will in the corners when folded down. There WON'T be any cuts in the liner.

Here's the picture progression:

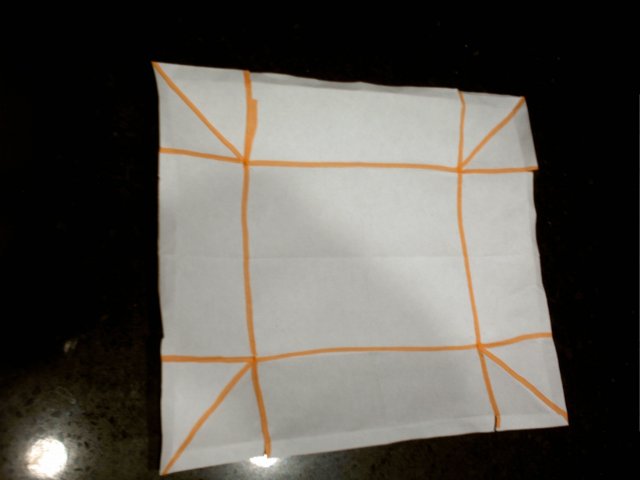

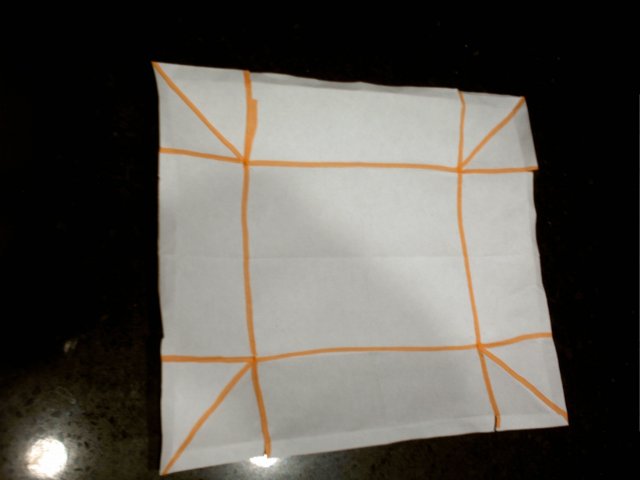

Liner flat

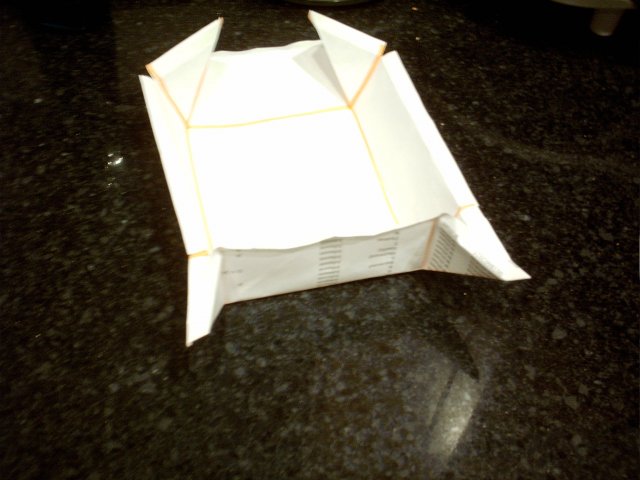

Long sides folded up

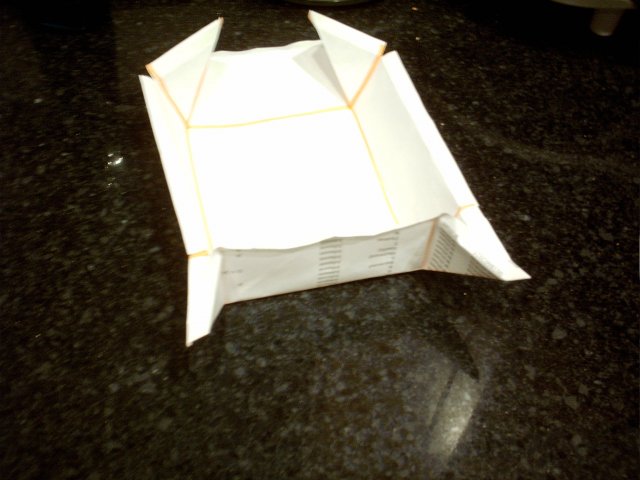

Short sides folded up (notice the triangle formed on each corner)

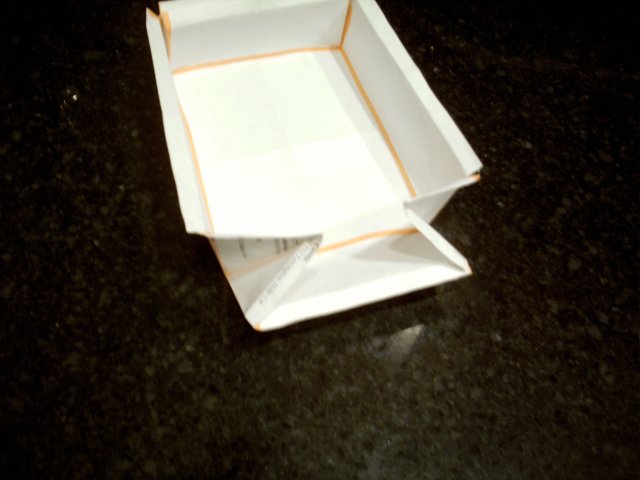

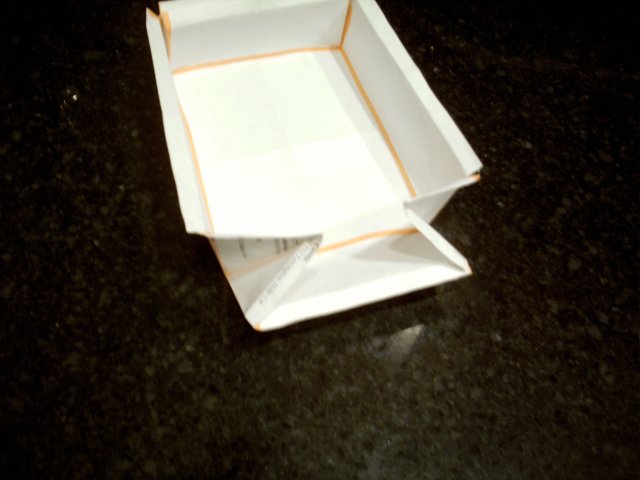

The difference between corners folded inside (top/normal) and outside (bottom/my way)

Another example of the folded inside normal way on the bottom

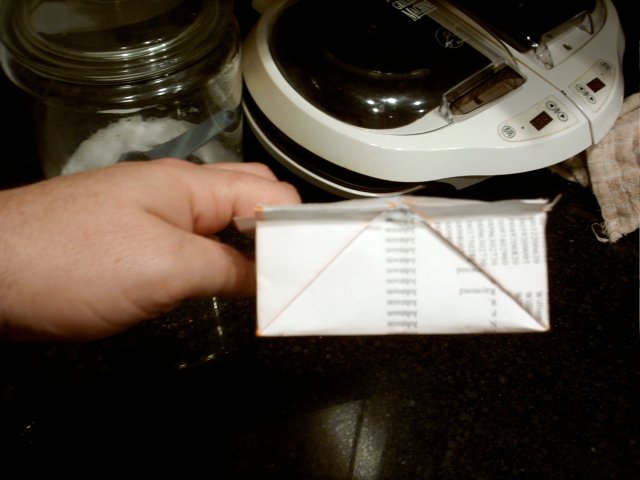

The folds on the outside my way between inside of tank and plywood

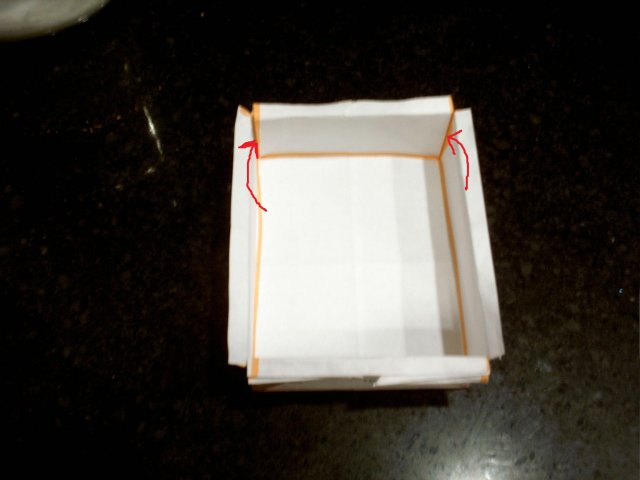

Clean inside lines with top folded down over the 6" walls of the tank. Notice how the fold is secured in the corners. No folds on the back and front.

Here's the picture progression:

Liner flat

Long sides folded up

Short sides folded up (notice the triangle formed on each corner)

The difference between corners folded inside (top/normal) and outside (bottom/my way)

Another example of the folded inside normal way on the bottom

The folds on the outside my way between inside of tank and plywood

Clean inside lines with top folded down over the 6" walls of the tank. Notice how the fold is secured in the corners. No folds on the back and front.