Bought a house...came with a tank.

- Thread starter branflake12

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alright heres the update:

The skimmer has been removed. I now have 3 powerheads in the tank, the two original Maxi Jet (1200's...used the vinegar trick from greech) and a brand new Koralia 750 GPH. THe two maxi's are pointed out towards the reef mid water, and they also get some surface agitation. THe new one is pointed down from about half way in the tank at the rock and sand.

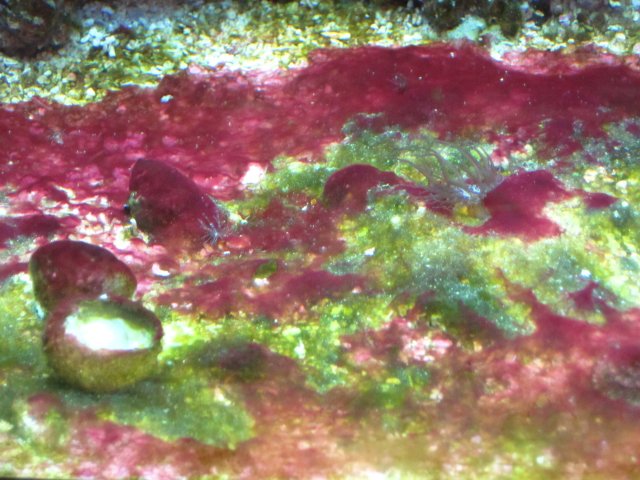

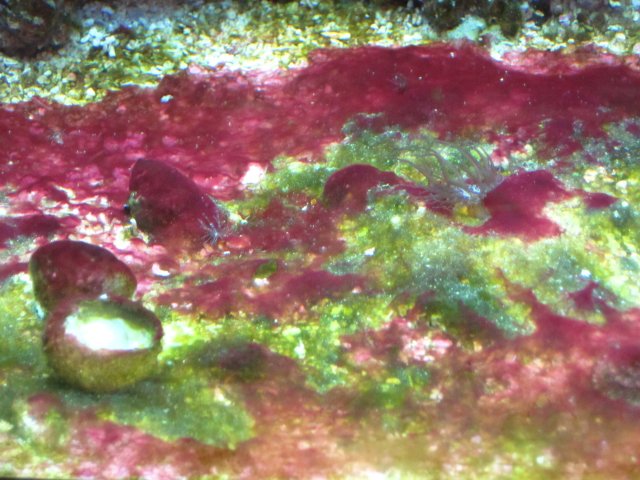

The aptasia was "at bay" and now its just flooding back with lots of little ones (see pics). I still have a big cyano problem...its strongest at night (when these were taken) in the mornings its barley there. I am also getting some green algae growing on the bottom and a few rocks. Hope the new powerhead helps. I also have a large number of empty snail shells collecting in the bottom, but still have lots of snails cruising around. Do i remove them? Should I put the skimmer back in-would it help at all?

I have more Joes Juice on the way, and something to cure the cyano (not an antibotic...cant remember now what it was, LFS recommended it and found it online for 1/5th the price.)

The tank is now braced down the center with wood and metal and I am happy with the results.

The skimmer has been removed. I now have 3 powerheads in the tank, the two original Maxi Jet (1200's...used the vinegar trick from greech) and a brand new Koralia 750 GPH. THe two maxi's are pointed out towards the reef mid water, and they also get some surface agitation. THe new one is pointed down from about half way in the tank at the rock and sand.

The aptasia was "at bay" and now its just flooding back with lots of little ones (see pics). I still have a big cyano problem...its strongest at night (when these were taken) in the mornings its barley there. I am also getting some green algae growing on the bottom and a few rocks. Hope the new powerhead helps. I also have a large number of empty snail shells collecting in the bottom, but still have lots of snails cruising around. Do i remove them? Should I put the skimmer back in-would it help at all?

I have more Joes Juice on the way, and something to cure the cyano (not an antibotic...cant remember now what it was, LFS recommended it and found it online for 1/5th the price.)

The tank is now braced down the center with wood and metal and I am happy with the results.

Looks like a massive improvement after your cleaning job. Kudos as the time maintaining is much easier than the initial cleanup.

Nice job on what looks to be a fun beautification.

Nice job on what looks to be a fun beautification.

If you have hermit crabs in the tank, I would leave the snail shells, as they are potential homes for them. If you don't like seeing the empty shells (my wife doesn't), you can pick them up and move them to a not so visible area of the tank.

If the skimmer is functioning properly, yes, it can help you. I would put it back on the tank if you're able to get it working like it should.

If the skimmer is functioning properly, yes, it can help you. I would put it back on the tank if you're able to get it working like it should.

I realize that I am a bit late to this discussion and that I am not an expert in tank building but, I do have an engineering background and can see how the forces that the water places on the glass surfaces are dealt with in each of the different tank systems.

The standard tank with a plastic rim and center braces works by the water putting a force on the glass walls. These forces is then transferred to the plastic rim all round the tank and then finally transferred to the center brace, which is canceled by the equal force on the opposite wall. In effect, most of the force is taken up by the center brace that is under continuous tension. The width of this centre brace is sized (usually inch or two wide) so that the plastic is strong hold up against this tension. Since the glass walls are pushing against the rim (the rim being on the out side of the tank), the rim dose not even have to be glued on. The rim glue is not part of the support structure of the tank; it is only there to keep the rim from sliding off the top of the tank.

The Euro type tank uses a rim of glass around the inside edge of the tank with one or two center braces (as you can see in Ace25’s pictures). Here the water places a force on the glass walls, which is transferred to the inside rim using the glue as part of the structure. The force is then canceled by the glass strip not wanting to bend. However, this is done across the entire length of the glass edge, spreading the load across that entire edge and glue joint. So, if you have a 48” tank, it has 48” taking up the load. This is 48 times less load per inch, then in the example of a standard tank with a 1” center brace. Spreading the load on the joint, keep the joint strength within the capacity of the silicone glue’s adhesion to the glass. In effect, the Euro tank bracing works much like the bottom glass of the tank. The Euro tank has cross braces to compensate for the fact that we need an opening on the top, wide enough to access the inside of the tank, unlike the bottom of the tank which is solid piece of glass. The wider the strips of glass running along the edge of the tank (the less tendency for the glass to bend) used, the less of a need for a center brace (or at least narrower stripes are needed for the center brace).

The Euro and Standard tanks use two completely different systems to deal with the forces being place on the wall of the tank by the water in the tank. Blending the two system can be done, but must be done carefully. In my opinion, just replacing the center brace of a plastic frame with an equal size glass brace glued to the glass wall is not safe. You would need a much wider glass strip (as Ace25 shows in his first pic example) then the original plastic brace so that there is enough glue area to hold the pressures. Otherwise the join will eventually fail, maybe a few days, a few months, or if your lucky a few years, but you will never know when.

Over the years (at least 30) I have had the center brace fail one several 55 gallon tanks, I usually replace it with a new tank and sell or give the old one to someone needing a critter tank. Dealing with the uncertainty is just not worth it.

The standard tank with a plastic rim and center braces works by the water putting a force on the glass walls. These forces is then transferred to the plastic rim all round the tank and then finally transferred to the center brace, which is canceled by the equal force on the opposite wall. In effect, most of the force is taken up by the center brace that is under continuous tension. The width of this centre brace is sized (usually inch or two wide) so that the plastic is strong hold up against this tension. Since the glass walls are pushing against the rim (the rim being on the out side of the tank), the rim dose not even have to be glued on. The rim glue is not part of the support structure of the tank; it is only there to keep the rim from sliding off the top of the tank.

The Euro type tank uses a rim of glass around the inside edge of the tank with one or two center braces (as you can see in Ace25’s pictures). Here the water places a force on the glass walls, which is transferred to the inside rim using the glue as part of the structure. The force is then canceled by the glass strip not wanting to bend. However, this is done across the entire length of the glass edge, spreading the load across that entire edge and glue joint. So, if you have a 48” tank, it has 48” taking up the load. This is 48 times less load per inch, then in the example of a standard tank with a 1” center brace. Spreading the load on the joint, keep the joint strength within the capacity of the silicone glue’s adhesion to the glass. In effect, the Euro tank bracing works much like the bottom glass of the tank. The Euro tank has cross braces to compensate for the fact that we need an opening on the top, wide enough to access the inside of the tank, unlike the bottom of the tank which is solid piece of glass. The wider the strips of glass running along the edge of the tank (the less tendency for the glass to bend) used, the less of a need for a center brace (or at least narrower stripes are needed for the center brace).

The Euro and Standard tanks use two completely different systems to deal with the forces being place on the wall of the tank by the water in the tank. Blending the two system can be done, but must be done carefully. In my opinion, just replacing the center brace of a plastic frame with an equal size glass brace glued to the glass wall is not safe. You would need a much wider glass strip (as Ace25 shows in his first pic example) then the original plastic brace so that there is enough glue area to hold the pressures. Otherwise the join will eventually fail, maybe a few days, a few months, or if your lucky a few years, but you will never know when.

Over the years (at least 30) I have had the center brace fail one several 55 gallon tanks, I usually replace it with a new tank and sell or give the old one to someone needing a critter tank. Dealing with the uncertainty is just not worth it.

Thanks for explaining that. Due to how its put into the house, Ill have to either leave it as i have repaired it, hope it lasts 5 years and sell the house, do further reinforcements or drain it and break the glass to get it out. There isnt room to get a peice of paper between the side walls and the tank rim.

I fully understand your dilemma; I just would hate to see all your hard work end up on the floor. I also don’t want to discourage you so that you do away with the tank, as I am sure that you will find many hours of enjoyment as time passes.

One other thought. If the spacing around the rim is so tight, is the rim (front and back side of the tank) actually pressing against the inside of the wall structure (i.e. a wall stud or something). If so, then you most likely will not have a problem, as the wall structure is handling the load that the water is putting on the glass. If not, is there anyway you can put a shim between rim and a support member of the wall?

Good luck and enjoy!

One other thought. If the spacing around the rim is so tight, is the rim (front and back side of the tank) actually pressing against the inside of the wall structure (i.e. a wall stud or something). If so, then you most likely will not have a problem, as the wall structure is handling the load that the water is putting on the glass. If not, is there anyway you can put a shim between rim and a support member of the wall?

Good luck and enjoy!

Update:

I have two peppermint shrimp in the tank that I hoped would (slowly)tackle the aptasia issue. I see them roaming around, but never eating the stuff. Between $25 for two shrimp and $6/bottle for joes juice, I need another alternative. The red/purple mushrooms appear to be getting more dispersed throughout the tank.

Question: can i "transplant" or otherwise encourage more mushroom coverage? Becuase if it has a mushroom on it...it wont have aptasia on it.

Am also seeing a bit more hairlike green algae. the snails are eating it (i can see "paths") but not fast enough. with the cyano gone thumbsup

thumbsup , the wavy green stuff is taking hold. I just want a clean bottom and rocks.

, the wavy green stuff is taking hold. I just want a clean bottom and rocks.

I have been taking one aptaisia encrusted peice of rock out at a time and leaving it outside for several days and putting it back. turns it white, but at least it kills the things.

SG is at 1.026 at water change time (after a week of evap, sometimes i dont have enough left over to top up with). I need to do another round of water tests and post up and see if that sets off any alarms with any of you.

My wife would like a "nemo" anemone for the clowns to play in like they do at the LFS. I wont be spending $100 on a wavy tentacle thing, so i was wondering what other corals/anemone type things I could add to the rock that are both easy and cheap.

Also noted last night is what appears to be a very small earthworm (part i could see was maybe 1"). Looked darn close to what i use to catch bluegill when i was a kid. No pics yet, any ideas? Problem?

I have two peppermint shrimp in the tank that I hoped would (slowly)tackle the aptasia issue. I see them roaming around, but never eating the stuff. Between $25 for two shrimp and $6/bottle for joes juice, I need another alternative. The red/purple mushrooms appear to be getting more dispersed throughout the tank.

Question: can i "transplant" or otherwise encourage more mushroom coverage? Becuase if it has a mushroom on it...it wont have aptasia on it.

Am also seeing a bit more hairlike green algae. the snails are eating it (i can see "paths") but not fast enough. with the cyano gone

I have been taking one aptaisia encrusted peice of rock out at a time and leaving it outside for several days and putting it back. turns it white, but at least it kills the things.

SG is at 1.026 at water change time (after a week of evap, sometimes i dont have enough left over to top up with). I need to do another round of water tests and post up and see if that sets off any alarms with any of you.

My wife would like a "nemo" anemone for the clowns to play in like they do at the LFS. I wont be spending $100 on a wavy tentacle thing, so i was wondering what other corals/anemone type things I could add to the rock that are both easy and cheap.

Also noted last night is what appears to be a very small earthworm (part i could see was maybe 1"). Looked darn close to what i use to catch bluegill when i was a kid. No pics yet, any ideas? Problem?

Peppermint shrimp -- Give them some time. A few of the ones I've had wouldn't touch aiptasia for weeks, then all of sudden the aiptasia were gone within a 2 - 3 day period. They typically do not eat the really large aiptasia, so if you're going to use Joe's Juice or another product to kill the aiptasia, I'd suggest focussing your efforts on those larger ones and leaving the smaller ones for the peppermint shrimp.

Aiptasia needs only a minimal space to take hold. It can even hold onto another coral, so you can't really prevent them from growing just by having all your rock, sand, and glass covered with corals.

The snails will catch up with the algae, especially if your water changes are large enough and frequent enough to be impacting the nutrient levels in the tank that are fueling the algal growth. If they don't seem to be doing so, adding a couple more may be necessary. Just be cautious, as once the algae is gone, their main food source is, too, and they can starve to death if there's not enough other stuff for them to forage on in the tank.

Inexpensive anemone substitutes = a hammer / frogspawn / torch coral. There's no guarantee the clowns will host in it, but there's no guarantee they'll host an anemone you buy either. Try not to get a frag that's too small or in poor health. The clowns will be a little rough on it and the coral will need to be able to handle it while it gets use to what they're doing.

As for the worm... There's many different worms... Without a better description or a pic, anything is just a guess. Bristle worm, peanut worm, spaghetti worm, etc... Browsing a hitch hiker ID page might be the best way to try and figure out what it might be at this point. Most of the commonly found worms are nothing to worry about.

Aiptasia needs only a minimal space to take hold. It can even hold onto another coral, so you can't really prevent them from growing just by having all your rock, sand, and glass covered with corals.

The snails will catch up with the algae, especially if your water changes are large enough and frequent enough to be impacting the nutrient levels in the tank that are fueling the algal growth. If they don't seem to be doing so, adding a couple more may be necessary. Just be cautious, as once the algae is gone, their main food source is, too, and they can starve to death if there's not enough other stuff for them to forage on in the tank.

Inexpensive anemone substitutes = a hammer / frogspawn / torch coral. There's no guarantee the clowns will host in it, but there's no guarantee they'll host an anemone you buy either. Try not to get a frag that's too small or in poor health. The clowns will be a little rough on it and the coral will need to be able to handle it while it gets use to what they're doing.

As for the worm... There's many different worms... Without a better description or a pic, anything is just a guess. Bristle worm, peanut worm, spaghetti worm, etc... Browsing a hitch hiker ID page might be the best way to try and figure out what it might be at this point. Most of the commonly found worms are nothing to worry about.